The Port Kembla steelworks needs a new process line for handling “fines” from iron ore, operators BlueScope has said in a planning proposal.

Subscribe now for unlimited access.

$0/

(min cost $0)

or signup to continue reading

BlueScope has lodged a development application with Wollongong City Council to develop the new “sinter sequence”.

The new sequence would reduce reduce the amount of sinter fines generated, and would replace functions currently performed by mobile equipment and trucks.

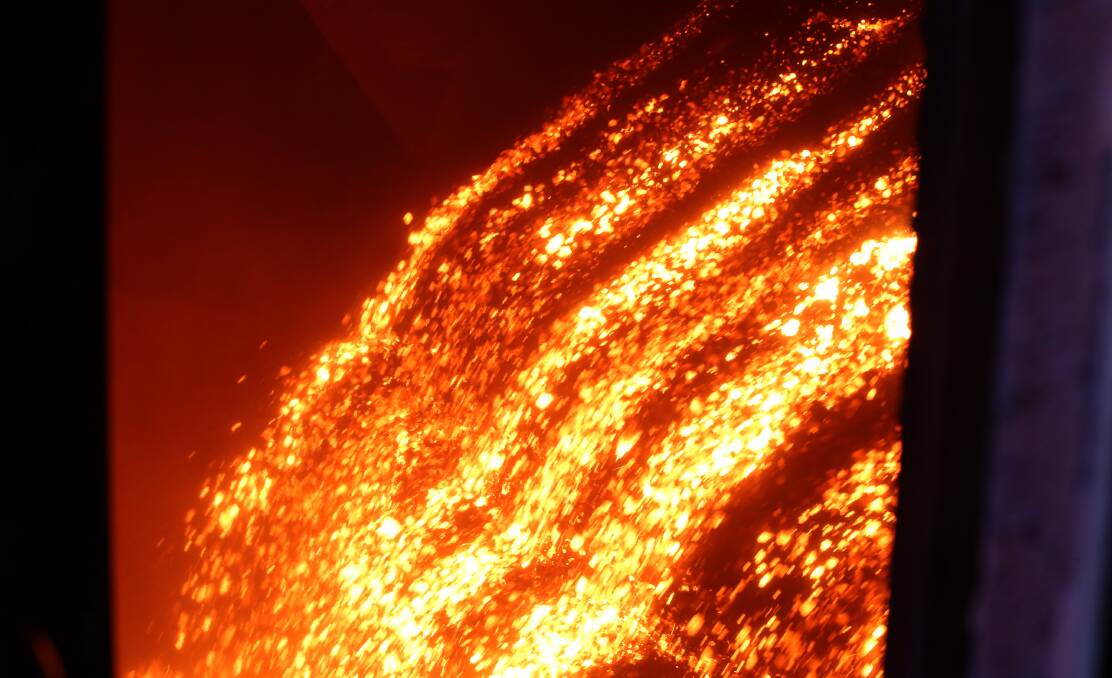

A screening process would separate the lumps from the smaller-grade dust-like particles, which would be fed back into the plant to be “agglomerated” at high heat into a larger, porous mass – a process called sintering.

This is so the larger materials can be fed into the blast furnace to make steel. if the ore is too fine, would get blown into the gas uptake equipment, or affect the the pressure inside the furnace.

The new sequence could operate 24 hours a day, seven days a week, processing about 240 tonnes of small sinter per hour.

BlueScope has proposed building this transfer system with conveyor belts covered at transfer points. A new structure would enclose the screening station where the finer particles were removed.

BlueScope said while fugitive dust emissions may be generated during construction, the net effect would be to remove 19,000 truck movements on internal steelworks roads each year.

As well as iron ore the “fines” contain a mix of coke, recycled iron, as well as purifying or cleansing chemicals called fluxes.

BlueScope said the development would conform with its existing pollution licences.