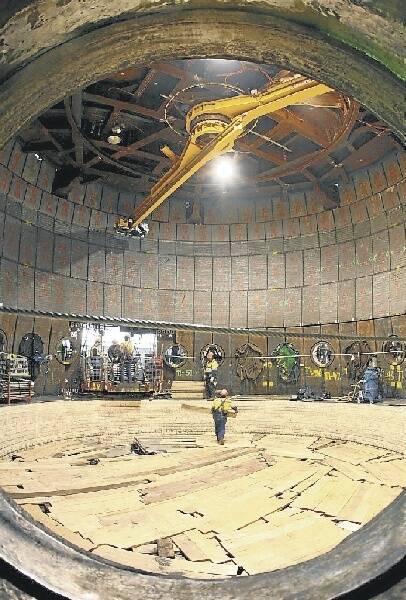

The heaviest lift of the 105-day, $370 million reline of BlueScope Steel's No 5 blast furnace at Port Kembla has been completed - with the reinstallation of the 143-tonne top section of the dust catcher.Project director Phil Shoard said the lift had been executed with extreme precision and without problems.The lift was not in the original reline plan but became necessary when engineers discovered a large internal component, the diffuser, needed to be replaced.The new 15m-high, 10m-diameter, 50-tonne diffuser was cut and rolled in one shift at the plate mill, by ABB Fab Shop, then welded together near Allans Creek before being connected to the top of the dust catcher.Mr Shoard said overall work on the Reline 09 shutdown project was now almost 90 per cent complete.Most of the mechanical contractors involved in the 105-day project had started reducing the size of their workforces on site as the largest capital investment project in the Illawarra for at least a decade neared completion."The bricking of the furnace hearth is now up to the tuyere level," Mr Shoard said. "The final closure of the furnace shell has commenced, with welding on of the tuyere plate. The Bosh level of refractory will then commence installation."The hot blast main, which was completely re-bricked, has now been heated to 350 degrees, to dry out the castable refractories."Mr Shoard said cold commissioning was well under way. The stockhouse had been 90 per cent cold commissioned and the new 870m-long belt on 501 conveyor had been run. The commissioning team has also been preparing for a number of pressure tests on the furnace this month. When they occur, around June 18, a 200m exclusion zone will be set up so the relined furnace can be checked for leaks.Much of the reline has been highly technical, but the pressure tests are conducted with a detergent-like substance, similar to checking a bicycle tube for leaks with water.

Subscribe now for unlimited access.

$0/

(min cost $0)

or signup to continue reading