Access to vast quantities of renewable energy will be key for the Illawarra to produce green steel, and areas where steelmaking hasn't occurred in the past but that are blessed with the potential for renewable energy could arise as competitors to the Illawarra's dominance of Australian steelmaking, new research has found.

Subscribe now for unlimited access.

or signup to continue reading

Just as historic steelmaking areas from the Illawarra to the Rhein-Ruhr region in Germany to Pittsburgh in the United States sprung up in close proximity to coal reserves, the steelmaking regions of the future will look to co-locate with renewable energy generation, a team of researchers from Monash University have found.

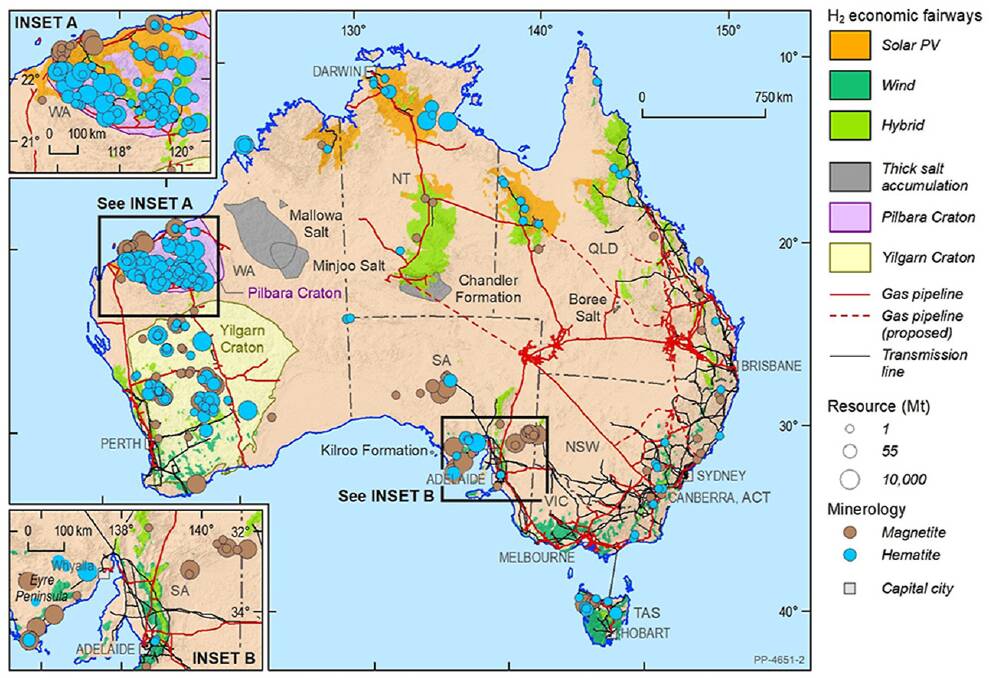

Their research, published in the peer-reviewed International Journal of Hydrogen Energy, found that the Pilbara in Western Australia and the Eyre Peninsula in South Australia were the Australian regions with high potential for green steel.

Key to these regions' potential is the co-location of iron ore reserves and the opportunity for large amounts of renewable energy generation to power electrolysers that would produce hydrogen to replace coal in steelmaking.

"We have these great sources of renewable power in terms of solar and wind across large swathes of the country, but one of the interesting things we noticed is that there's a strong correlation between the best parts around the country to produce hydrogen on a large scale and the parts of the country where we're producing large scale iron ore operations," co-author Stuart Walsh, senior engineering lecturer at Monash University, said.

While in the years since steelmaking first began near the coalfields of Europe and the United States it has become relatively cheap to ship coal to steelworks around the globe, hydrogen did not yet provide the opportunity for steelworks to be located close to other competitive advantages, such as cheap labour.

"First off, there's a lot of energy that goes into turning it into liquid hydrogen," Dr Walsh said. "In addition to that, the cost of just moving hydrogen around is expensive in and of itself, so if you can use it as close to a producer as possible, you have an additional benefit from that too."

While the authors did not specifically exclude the Illawarra - which currently produces the majority of the steel produced in Australia - they noted that there was the potential to tap into offshore wind generation to provide the energy needed for green steel production.

In both the Pilbara and South Australian case studies, the modelled steelworks were constructed with their own electricity generation, separate from the rest of the grid, to ensure the energy was 'green' without being drawn from a mix of energy sources as in the current east coast electricity grid.

As steelmakers around the globe experiment with potential technologies to produce green steel, the authors predict with potential from the automotive, aerospace and green building sectors to pay a premium for certified green steel, Australia had the chance to move from largely exporting the ingredients used in steelmaking to being a major global steelmaker.

"We have this fantastic renewable resource, the difficulty for Australia is exporting that renewable energy overseas, and steel gives us this vector where we can add value to the material, provide energy to the world and benefit ourselves as well," Dr Walsh said. "So it's a great opportunity if it can come to reality."

Our news app has had a makeover, making it faster and giving you access to even more great content. Download The Illawarra Mercury news app in the Apple Store and Google Play.